Case Study

Inventory Management and Quality Assurance System

We helped Nuflow streamline their production, warehouse, fulfilment and quality assurance by custom building an all in one system.

The client

Nuflow manufacture, sell and install pipe relining products. They produce custom-designed composite material and liners for specific commercial projects as well as stock plumbing supplies and.

With 50+ franchises throughout Australasia they needed an all in one warehouse and ecommerce platform that could services both their customer facing ordering and compliance responsibilities in the manufacturing process.

“This is a quote from the client about the success of the project etc.”

The problem

When we first met with the Nuflow team, they were using an assortment of off-the-shelf, and expensive software that didn’t integrate well, and was bloated with unused features.

They also relied on hand-written notes for tracking manufacturing details and batch-codes, which were critical for tracking and product recalls. Their manual fulfilment process was prone to human error.

Their online store was ‘tired’ and difficult for wholesale customers to use… it was too ‘retail’.

- Off-the-shelf software

- Paper office

- Manual processes

- Poor user-interface

- No pick-and-pack process

The solution

We designed and built a digital ecosystem that solves key manufacturing and wholesaling pain points.

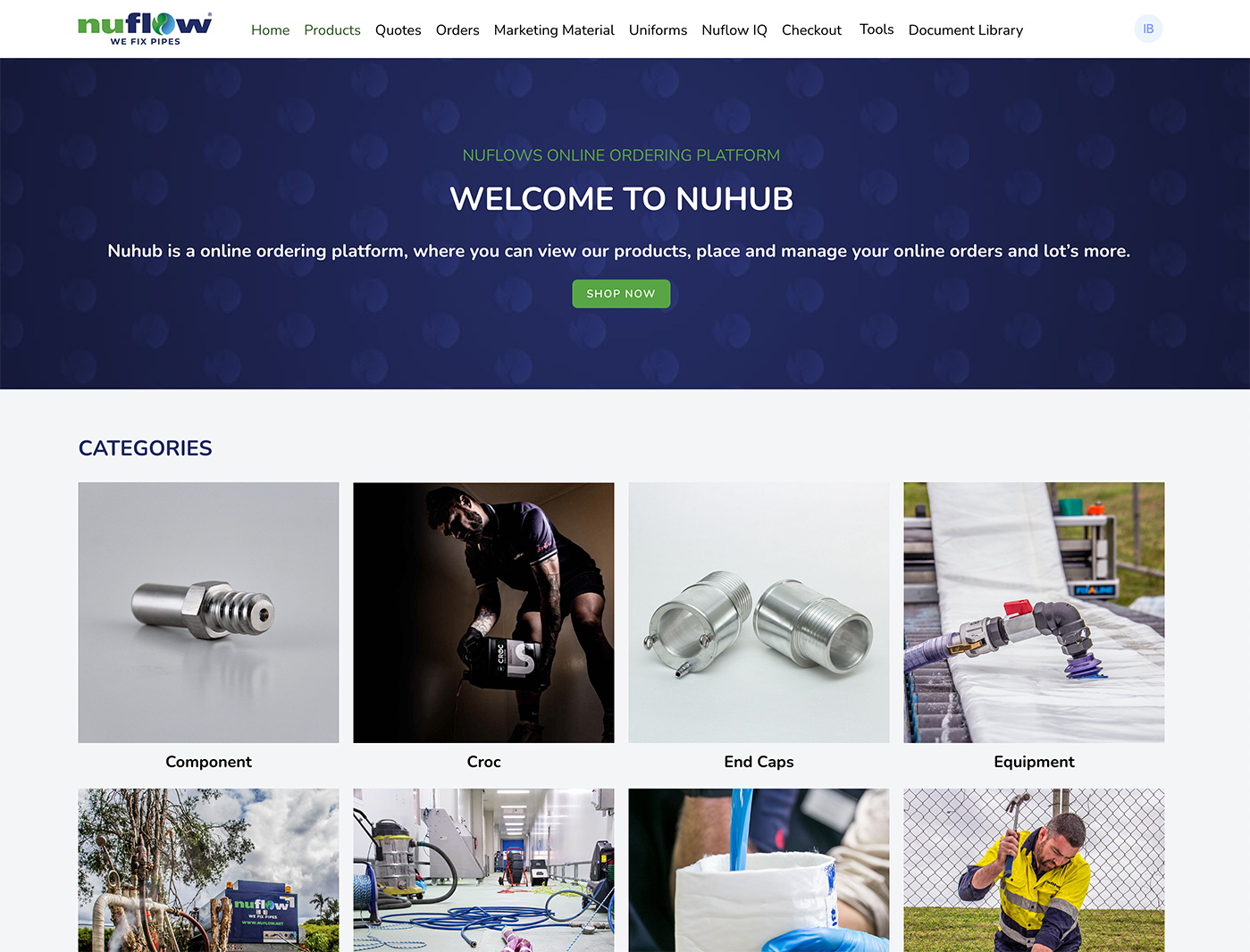

Customer Experience Design

The design and user journey of most online stores is geared towards retail sales, using large product images, ‘salesy’ content and a slow cart and checkout experience.

We designed a simplified, utilitarian interface, geared toward wholesale customers that already know what they need and are in a hurry.

Products are viewed in a list, with cart management built into the product list. Wholesale customers can easily scroll through product categories, and increase/decrease quantities without going back-and-forth through a cart.

Batch Codes and QR code scanning

The system autogenerates Batch Codes, which are converted into QR codes and printed as stickers.

Every product that is added as inventory is assigned to a batch-code, which is easily retrievable through scanning the QR code.

This allows Nuflow to store critical manufacturing information against each batch for referencing in the future. For example, this includes raw products, manufacturing dates, temperatures, and dimensions.

Customers can scan their QR code to retrieve instructional data sheets for specific products, as well as log warranties at the job site.

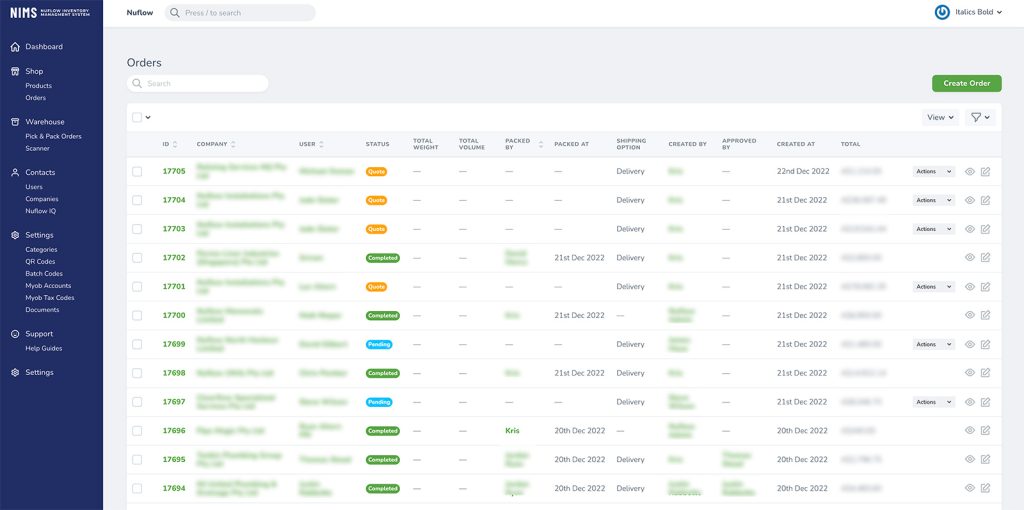

During fulfilment, warehouse staff can scan products within an order to ensure the correct products are picked, as well as keeping stock levels accurate. The system also tracks the staff member who picked the order.

Since this scanning process is all achieved from a smart phone, there is no need for expensive hardware.

Dashboard

At a glance, the team can view key metrics that help both fulfilment and manufacturing.

Warranties and Quality Assurance

Submitting and tracking Warranties was previously a very manual process. We setup a web app flow for installers to submit their jobs where Nuflow products are used. The installer can scan in the QR code for each product, log their GPS location and take photos of the job site for future reference. All from the browser of a smart phone.

Integration with MYOB

We integrated the system with MYOB Accounting Software. Customer, Product and orders are synchronised, which streamlines their invoicing flow and accounts reporting.

Technology

“This is a quote from the client about the success of the project etc.”